하모니 개발 장비

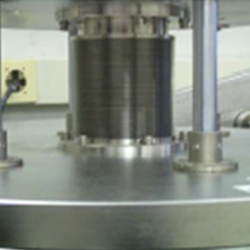

Combi Co-Sputter

Combinatorial multi-target co-sputtering system

- 3 target guns (2 inch diameter)

- Overlapping of 3 target source materials

(more than 400 combinatorial thin film chips on a 4-inch wafer) - Moving shutter

- Heater for substrate

Application

- Fabrication of non-volatile memory capacitor

(for PRAM, MRAM and FRAM) - combi-array for development of new metallic materials

Specification

| Deposition Temperature | R.T. ~ 500℃ |

| Deposition Pressure | 10⁻⁷ ~ 10⁻¹ Torr (Turbomolecular Pump) |

| Thermal Uniformity | -1 ~ +1% (at 4 in water) |

| Process Gas | Ar, N₂, O₂ |

controller

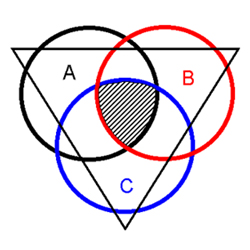

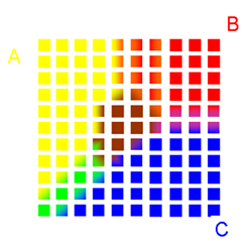

Natural composition spread

Square discrete library spread

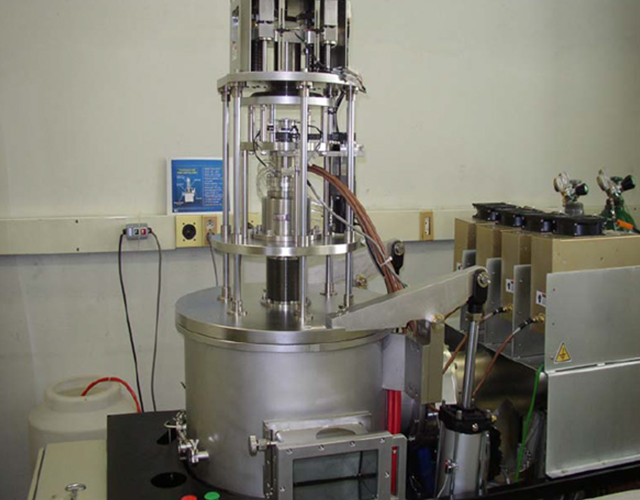

Combi Multi-Target Sputter

Combinatorial multi-target sputtering system

- 4 target guns (4 inch diameter)

- Easiness of target gun change

(target gun rotation part & target gun up-down part) - moving shutter (for concentration gradient)

- 2500 chips/wafer

- All the process controlled by computer program

Application

- Fabrication of non-volatile memory capacitor

(for PRAM, MRAM and FRAM) - combi-array for development of new metallic materials

Specification

| Deposition Temperature | R.T. ~ 500℃ |

| Deposition Pressure | 10⁻⁷ ~ 10⁻¹ Torr (Turbomolecular Pump) |

| Thickness Uniformity | -3 ~ +3% (at 4 in water) |

| Thermal Uniformity | -1 ~ +1% (at 4 in water) |

| Process Gas | Ar, N₂, O₂ |

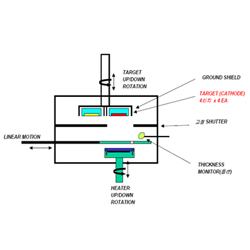

Schematic drawing

Target gun rotation part

Target gun up-down part

LSMCD-Explorer

Liquid source misted chemical deposition system

- Moving shutter (for concentration gradient)

- Excellent uniformity of combi-array (mixing liquid sources)

- Easiness of composition control

- All the process controlled by computer program

Application

- Fabrication of non-volatile memory capacitor

(for PRAM, MRAM and FRAM) - combi-array for development of new metallic materials

Specification

| Deposition Temperature | R.T. ~ 200℃ |

| Deposition Pressure | 10⁻⁷ ~ 760 Torr (Rotary Pump) |

| Thickness Uniformity | -3 ~ +3% (at 4 in water) |

| Thermal Uniformity | -1 ~ +1% (at 4 in water) |

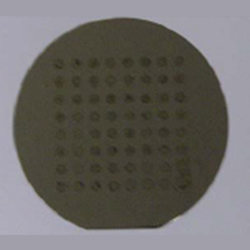

Ferroelectric combi-chip

Moving shutter

controller

PolyCat Accelerator

Parallel Polymerization Reactor System

- Individually Controlled Temperature and Pressure

- Designed by CUPS researchers

- Obtained Patent (KR0322689)

- controlled by Lab-view software

Application

- Optimizations of Olefin Polymerization Conditions

- High-Throughput Screening for Olefin Polymerization Catalysts

- High-Throughput Screening for Organic Reaction Catalysts

Specification

| Number of reactors | 8 |

| Reactor volume | 20cc |

| Reactor material | Stainless steel with glass vessel |

| Reactor temperature | R.T ~ 90℃ |

| Reactor pressure | 1 ~ 10 atm |

| Stirring speed | 0 ~ 600 rpm |

| Anaerobic condition | Available |

| Vacuum | Available |

Operation Software

8 reactors

One reactor including a 20 mL glass vessel

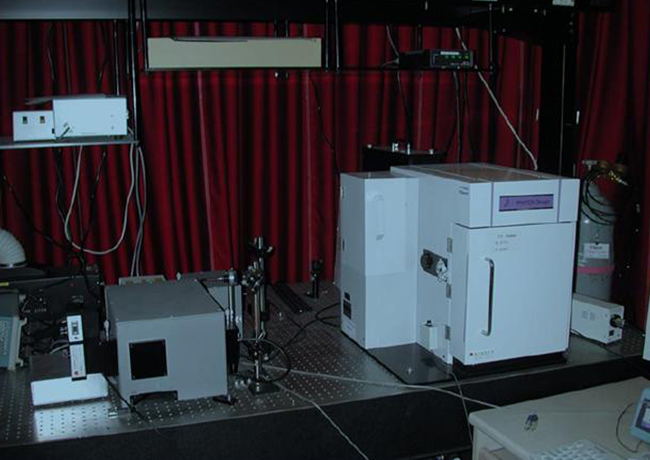

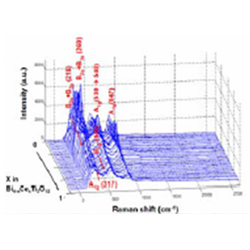

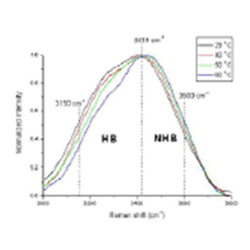

Micro Multi Spectrometer

Micro-Raman/UV-VIS/Fluorescence Spectrometer

- Scanning & Image mapping

- Sample type : liquid, powder, thin film

- X Y manipulation controlled by computer (resolution < 1 μm)

Application

- Characterization of several materials

(Electronic materials, Catalyses, Biomaterials, Carbon materials) - Chemical reaction analysis

- Fluid analysis inside microchannels

Specification

| [source] Raman UV/VIS, Fluorescence |

Ar ion laser (488nm) Deutrium lamp (UV, 185 ~ 350 nm) Tungsten lamp (VIS, 350 nm) |

| [Spectra range] Raman UV/VIS, Fluorescence |

-25 ~ 4000 cm 230 ~ 1000 nm |

| CCD detector | 1340 x 400 pixels |

| Sample size | > 5 μm |

| Scan range | 100 x 100 mm² (200 x 200 array) |

Library sample

Thin film sample data

Liquid sample data

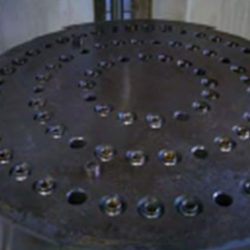

SUPER-I

Successful Ubiquitous Parallel Economic Reactor

- Top-loading Graphite seals

- Removable cartridge for rapid reloading

- Flow-Equalization Capillaries

- Controlled by Lab-view software

Application

- Most of heterogeneous catalytic reaction

ex) DeNOx reaction

Oxidative dehydrogenation of light alkanes

Oxygenation of hydrocarbon etc.

Specification

| Sealing material | Graphite gasket |

| Number of reactor | 64 |

| Reactor well volume | 0.5cc |

| Catalyst weight | 10 ~ 200 mg |

| Reactor material | Stainless steel |

| Reactor temperature | R.T ~ 450℃ |

| Reactor pressure | Ambient |

| Flow rate | Up to 30sccm/well |

| Analysis | Online connection to GC, MS |

Reactor Body

Inner view of reactor body

Library sample

SUPER2

Successful Ubiquitous Parallel Economic Reactor

- Individual temperature control

- High temperature reaction

- Removable quartz reactor for rapid reloading

- Flow-Equalization Capillaries

- Controlled by Lab-view sofrware

Application

- Most of heterogeneous catalytic reaction

ex) DeNOx reaction

Steam and CO₂ Reforming

Partial oxidation of hydrocarbon etc.

Specification

| Sealing material | Graphite |

| Number of reactor | 32 |

| Reactor size | ¼ inch |

| Catalyst weight | ~ 500 mg |

| Reactor material | quartz |

| Reactor temperature | R.T ~ 1000℃ |

| Reactor pressure | 1 atm |

| Flow rate | Unlimited |

| Analysis | GC or MS |

Reactor Body

Output connection

View of reactor system

Combinatorial Metal Evaporator